Outdoor bar table/bar cart How-to

So as Anna mentioned yesterday, I am taking over for the day for a little woodworking lesson. Technically speaking this is a stationary table. What is good about the design and materials is that it can easily be turned into a cart by shortening the legs and slapping the wheels of your choice on the bottom.

This may seem like a complicated process at first glance, but it is surprisingly simple and can easily be complete by a novice at woodworking. This was my first furniture project designed and built from the ground up, and I would in no way consider myself highly skilled in woodworking. As such, it is an ideal project for a first timer, especially considering the relatively low cost.

In addition you can use this same design to create your own coffee table by simply subtracting one shelf and shortening the legs.

Required Materials

1 box 1⅝in screws

1 box 1¼in screws

1 box ½in hardwood plugs

4 1x4x8 boards

6 2x2x8 boards

1 2x12x8 board

1 can of stain

1 can of varnish

Total cost: under $70 – all boards are standard “whitewood” (southern pine)

Suggested tools

Power drill

Phillips screw driver bit

½in spade bit

3/32in drill bit

coarse sand paper

saw (table or miter works best but any saw will do, including a hand saw)

3 or 4 clamps (I prefer Bar or C clamps)

hammer or mallet

wood glue (not required but suggested)

1. Select wood

No pressure treated wood. It is critical to select the straightest possible boards. Also take notice of the moisture in the wood. If it is noticeably wet at the time of purchase it may warp upon drying.

2. Cut wood

Halve the 2x12x2 at the store – remeasure once these are brought home as they may require slight trimming to make even. I like to rip about ¾ of an inch lengthwise off the joint side of these boards so they fit cleaner, but this is not necessary if you don’t have the equipment.

8 – 38in 2×2’s (sides of frame and shelves)

4 – 34½in 2×2’s (legs)

8 – 1 ¾in 2×2’s (sides of frame and shelves)

22 – 15⅝in 1×4’s (slats for the shelves)

After cutting, sand down the cut edges slightly.

3. Assemble underframe and legs

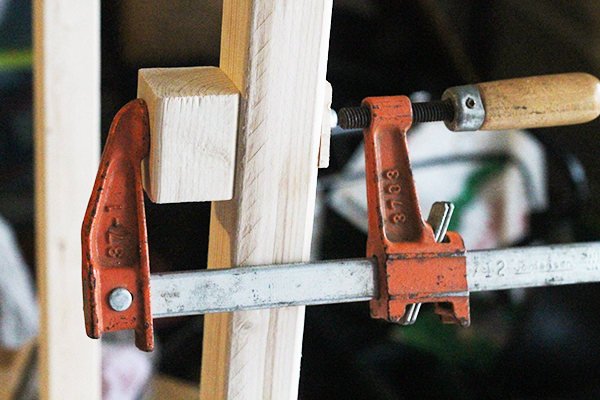

Use scrap 2×2’s and the clamps to set the corner as seen in the picture.

Place leg in the corner and hold in place. Using the spade bit, drill into the legs between

⅜in and ½in where the screws will secure the leg to the frame. Then use the 3/32 bit to

Drill pilot holes into the spade bit holes.

Before inserting screws place small amount of wood glue at the inner joint where the leg and sides meet. Secure with 1⅝in screws and repeat process for 3 remaining corners.

4. Secure frame to the table top

Lay the 2×12’s top down and center the frame on top. Use clamps to stabilize the frame to the top.

Using the spade bit and 3/32 bit, pre drill holes in the bottom of the frame and secure with 1⅝in screws.

5. Add second layer of sides to frame

Place second layer of 2×2’s on underside of the frame. Pre drill holes using the drill bits previously mentioned. Be sure to offset these holes with the screws used to secure the

Frame to the top. Finish with 1⅝in screws.

Secure the sides of the second layer to the legs with the same system of pre drilling and glue described in step 3.

6. Assemble shelves

With the table still top down, align the slats across the frame. Slide 38in 2×2’s between the legs and align with the edges of the slats. Drill pilot holes as described previously and secure with 1¼in screws.

7. Attach shelves

Using a clamp, secure a scrap 2×2 to the desired height of the shelf to each leg. Take your finished shelf and rest it on top of the clamped 2×2 scraps. Double check the height of each corner and secure shelf to the legs using the procedure described in step 3. Repeat for the second shelf. Then add the remaining 12¾in 2×2’s to the legs next to each shelf.

8. Fill holes

Turn table right side up for the first time.

Insert the ½in hardwood plugs into the visible drill holes. Be sure that they are inserted straight.

Hold a scrap 2×2 on top of the plug and tap with a hammer or mallet until plug is flush with the surface of the table. Then lightly sand over the top of the inserted plug to smooth the area.

Repeat for each visible hole.

9. Stain and varnish

Follow directions on the can.

I used spar varnish because my wife wants to primarily use it outside and a spar varnish will provide better moisture and UV protection. If it will primarily be used inside a polyurethane varnish will work fine. Slap on at least two coats.

I hope this is clear enough and gives you the confidence to give it a try. Feel free to email us with any questions and I would be happy to help!

– Gabe

P.S. More DIYs for the home here.

All photos by the talented Kathryn McCrary Photography. To see how we use this on our patio, see our patio makeover.